Yes! Foodline frozen french fries production line was successfully exported to Canada. Contact us to get the frozen french fries production line price.

Frozen French Fries Production Line Price in Canada

Daniel Morrison from Ontario, Canada wanted to invest the food processing business. He rented a new warehouse to install the frozen french fries production line. Then he discovered Foodline Machinery.

Technical Parameters of frozen french fries production line

| Cheaper And Europe Technology Potato Chips Making Forming Machine CE Certificate | |||

| Item | Capacity 60-1000kg per hour | Semi Aumatic For Small Capacity 50-100kg/h | Full Automatic for Bigger capacity |

| Usage | French Fries Chips, Fried Potato chips, Frozen Potato Chips | ||

| Fule | Natural Gas, Electricity, Diesel | ||

| Worker Qty | up to Production Capacity | 4-8 | 4-12 |

| Material | SS304 Food Grade | ||

| Raw Material Request | Fresh potato, no rotten, no degenerative, no insect pests or other defects. | ||

| Smooth on the surface, no groove in the head, little small buds or no bud should be better, no flaw or hollow. | |||

| Dry matter content ≥21%, starch content ≥15%, reducing sugar ≤0.25 | |||

| Weight of unit potato should be among 150g~500g, the best brand of POTATO is Shapody. | |||

| Brand | PLC AND Electronic Spare parts ARE SIEMENS and Delter | ||

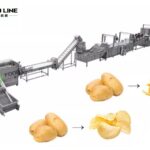

Frozen French Fries Making Machine

The frozen French fries making machine is a complete processing line designed to convert raw potatoes into ready-to-pack, frozen French fries. It automates all stages from peeling, cutting, blanching, dehydrating, frying, cooling, freezing, to packaging.

After months of researching, comparing manufacturers from Europe to Southeast Asia, Daniel stumbled upon Foodline Machinery, a reputable equipment supplier based in China.

What caught his eye?

- A fully automatic Frozen French Fries Production Line

- Stainless steel construction compliant with international food safety standards

- Customization options for output capacity (perfect for scaling gradually)

- End-to-end solutions—from washing and peeling to frying, freezing, and packaging

He reached out. Within 24 hours, Foodline’s export manager, Eva, responded with technical specs, a proposed layout, and a walkthrough video of a recent client installation.

“The communication was top-notch. I felt like I wasn’t just buying a machine—I was gaining a business partner,” Daniel said.

From Potatoes to Profits: The Setup

The production line Daniel ordered included:

- Potato washing and peeling machine

- French fry cutter

- Blanching machine

- Dewatering machine

- Industrial fryer

- De-oiling machine

- Quick freezer

- Packaging machine

It arrived in Toronto port within six weeks. Foodline’s remote engineers helped his local team install and commission the line via video calls and real-time troubleshooting support.

In just three months, Daniel went from small-batch kitchen prep to producing up to 500kg of frozen French fries per hour.

What our client says?

The machine exceeded my expectations. From washing to freezing, every step is automated and efficient. Foodline’s support team was incredibly responsive during installation. Now I produce 500kg of fries per hour and just landed my first retail contract!

Interested in starting your own French fries production line?

👉 Contact Foodline Machinery today and get a quote with layout design and expert consultation—just like Daniel did.