Small scale candy making equipment is designed for experimental candy production, home workshops, and small confectionery businesses.

This compact candy production system can process soft candy, gummy candy, hard candy, and lollipops. It is an ideal solution for startups, R&D kitchens, and family-run candy workshops.

Low investment | Easy operation

Professional Small Candy Machine for Workshops, Labs & Startups

Small scale candy making equipment is a compact candy processing line consisting of three core machines:

- Cooling table

- Sugar cooking kettle

- Small candy depositing (forming) machine

Limited-Time Offer! Contact us today to get a discount! WhatsApp/Tel 008613598866720

Technical Parameters of Small Scale Candy Making Machine

| Model | FL-DA(Pouring type) | FL-DB(Plunger type) | FL-V(Pouring type) |

| Deposit Times | 30-60times/min | 30times/min | 20-35times/min |

| Productivity | 60-100kg/h | Pouring volume: 0.5-30g (±0.3) | 40-150kg/h |

| Voltage | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Power | 4.2kw | 4.2kw | 1.2kw |

| Nozzle/Piston | 10pcs | 10pcs | 20pcs |

| Machine Size | 1000*760*870mm | 800*1100*900mm | 804*660*1300mm |

| Weight | 100kg | 90kg | 320kg |

Features of Gummy Candy Make Machine

- Commercial-Grade Materials – Stainless steel, food-grade silicone, and professional polycarbonate

- Temperature Precision – Tools that ensure perfect soft-ball, hard-crack, and tempering stages

- Scalable Solutions – Grow from kitchen hobby to commercial production with compatible systems

- Community & Support – Access to recipes, troubleshooting guides, and expert advice

Types of Candy You Can Produce

Using small scale candy making equipment, you can produce:

- Lollipops

- Soft candy

- Gummy candy

- Hard candy

Different candy shapes and sizes are achieved by changing custom candy molds, making this equipment extremely flexible for diverse product lines.

Limited-Time Offer! Contact us today to get a discount! WhatsApp/Tel 008613598866720

Main Components of Small Scale Candy Making Equipment

1. Sugar Cooking Kettle (Candy Cooking Pot)

The sugar cooking kettle is the core unit of the candy making process.

Function:

- Heats the mixture until it reaches a thick paste or syrup state, suitable for forming

- Mixes and cooks white sugar, glucose syrup, and other ingredients

Applications:

- Hard candy

- Soft candy

- Lollipops

The kettle with mixer can ensure uniform heating and consistent candy texture, which is critical for quality candy production.

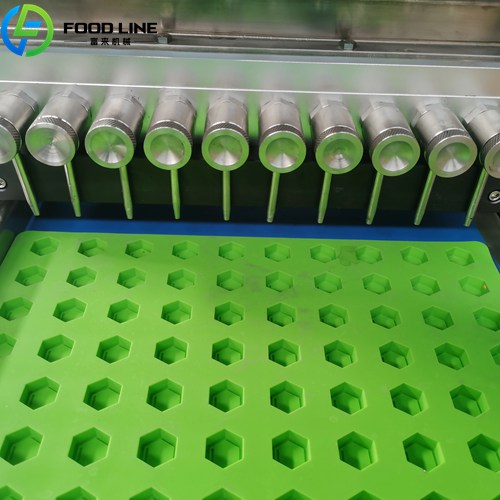

2. Small Candy Depositing & Forming Machine

The candy depositing machine controls accurate candy weight and shape.

Key features:

- Adjustable depositing weight (grams per piece)

- Precise pouring of hot sugar paste into molds

- Compatible with multiple mold types

How it works:

- Candy paste is poured into molds according to preset weight

- Different molds are used for soft candy shapes, hard candy sizes, or lollipop designs

- Ensures uniform candy appearance and consistent quality

3. Cooling Table

After depositing, the filled molds are placed on the cooling table.

Cooling process:

- Candy naturally cools and solidifies

- Ensures proper shape retention and surface finish

- After cooling, candies are ready for demolding and packaging

The cooling table plays a key role in achieving stable candy texture and easy demolding.

Get Started with Small Scale Candy Production

Looking to produce soft candy, gummies, hard candy, or lollipops on a small scale?

Our small scale candy making equipment can help you turn ideas into real products quickly and efficiently.

👉 Contact us today for machine specifications, pricing, and mold customization options.