Foodline industrial carrot peeling machine is designed to peel large batches of carrots quickly and uniformly. The Industrial Carrot Peeling Machine with Washing Function solves both problems in one go—removing dirt, outer skin, and impurities while maintaining the fresh, natural look of your carrots.

Technical Parameters of Carrot Peeling Machine

| Model | Dimensions (L×W×H) | Capacity (kg/h) | Power | Voltage | Key Features |

|---|---|---|---|---|---|

| Spiral Brush Machine | 2940×1120×1360 mm | 600-800 | 2 kW | 380V | Industrial-scale processing, connects to production lines |

| M80 | 1110×800×980 mm | 300-500 | 1.1 kW | 380V | Hard bristle brushes, friction cleaning with water spray |

| M100 | 1310×800×980 mm | 400-600 | 1.1 kW | 380V | Batch processing (30-40kg per load) |

| M150 | 1810×800×1000 mm | 800-1000 | 1.5 kW | 380V | Mid-range capacity for continuous operation |

| M180 | 2110×800×1000 mm | 1000-1500 | 1.5 kW | 380V | High-volume processing |

Note: All models can be customized for specific voltage options.

Advantages of Choosing Our Carrot Washing & Peeling Machine

- Labor Savings – Replaces multiple manual workers.

- Consistent Quality – Every carrot peeled to the same standard.

- Water-Saving Design – Circulating pump reduces waste.

- Durable Build – Long-lasting brushes and stainless steel body.

- Customizable Size – We can tailor machine dimensions and capacity.

How does commercial carrot peeler machine work?

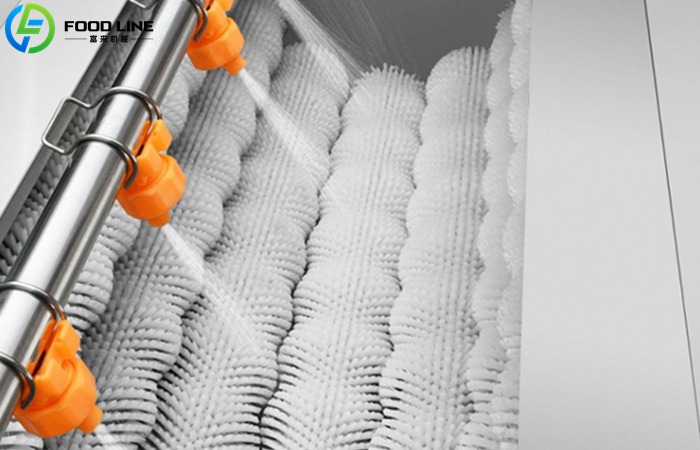

The machine uses rotating brush rollers combined with high-pressure water spray. As carrots tumble inside, brushes remove dirt, soil, and outer skin. The built-in washing section ensures carrots come out clean, bright, and ready for further processing.

How to Extend Brush Roller Lifespan in a Carrot Washing Machine

Brush rollers are the heart of the peeling system, and replacing them frequently can be costly. Here’s how to maximize their service life:

- Avoid Overloading – Too many carrots at once increases friction and brush wear.

- Rinse Before Loading – Removing excess mud or stones reduces abrasive damage.

- Adjust Pressure Correctly – Excessive peeling pressure can strip brushes faster.

- Regular Cleaning – Residual vegetable fibers can harden on brushes, reducing efficiency.

- Rotate and Replace Strategically – Swap heavily used rollers with less-used ones to balance wear.

By following these steps, many processors extend brush life by 30–50%, reducing downtime and costs.

Water Recycling Systems in Vegetable Processing Equipment

Water use is a major concern in high-capacity vegetable processing, both for cost and environmental impact. Our carrot peeling machine integrates a closed-loop water recycling system that:

- Filters Out Solids – Removes carrot peels, soil, and debris before water recirculation.

- Uses Multi-Stage Filtration – Fine mesh and sediment traps keep spray water clean.

- Reduces Fresh Water Use by Up to 70% – Lower utility bills and improved sustainability.

- Keeps Hygiene Standards High – Regular flushing and sanitation ensure food safety compliance.

This makes the machine ideal for eco-conscious factories aiming for greener operations without sacrificing cleaning performance.

Conclusion

If you want fast, hygienic, and uniform carrot peeling with minimal water waste, our Industrial Carrot Peeling Machine with Washing Function is your best choice. It’s built for high-volume production, energy efficiency, and long-term reliability.

📩 Contact us today to get a quote or customize your carrot peeling solution!