Looking for a commercial freeze dryer that combines performance, durability, and cost-efficiency? The FLFD series from Foodline delivers premium results for a wide range of industries—whether you’re freeze drying food, pet treats, pharmaceuticals, or nutraceuticals. These vacuum freeze drying machines are engineered for maximum efficiency, low energy use, and easy operation, making them ideal for both new and growing businesses.

Technical Parameters of commercial food freeze dryer

| Model | FLFD-NDO.2 | FLFD-ND1 | FLFD-NH5 | FLFD-NH10 | FLFD-NH20Z | FLFD-NH30Z |

| Drying Area(㎡) | 0.18 | 10 | 25 | 50 | 100 | 125 |

| Standard warehousing capacity(kg/container) | 0.6~1.5 | 8~10 | 50~80 | 90~120 | 150~200 | 300~800 |

| Number of Tray(pcs) | 2 | 4 | 12 | 20 | 56 | 68 |

| Size of Tray(mm) | 310*290*30 | 533*513*30 | 710*63*35 | 790*630*30 | 690*570*30 | 710*630*35 |

| Size of total machines(m) | 1630*850*1900 | 2000*1300*2000 | 5300*2300*2900 | 6300*2300*2900 | 8000*2700*3500 | 8500*3100*3500 |

| Electric heating Power(kw) | 3.7 | 12 | 55.1 | 93.6 | 145 | 121 |

What Is Freeze Drying?

Freeze drying (also known as lyophilization) is a cutting-edge preservation technique. It involves freezing the product, reducing the surrounding pressure, and allowing the frozen water to sublimate—turning directly from solid to vapor without passing through a liquid phase.

This method preserves:

- Taste, color, and bioactivity

- Nutrients

- Structure and appearance

Perfect for extending shelf life without sacrificing quality.

Advantages of Freeze Drying

- Preserves Nutritional Value: Retains up to 97% of nutrients.

- Extended Shelf Life: Store freeze-dried food for up to 25 years.

- Unmatched Taste and Texture: Fresh-tasting food that’s visually appealing.

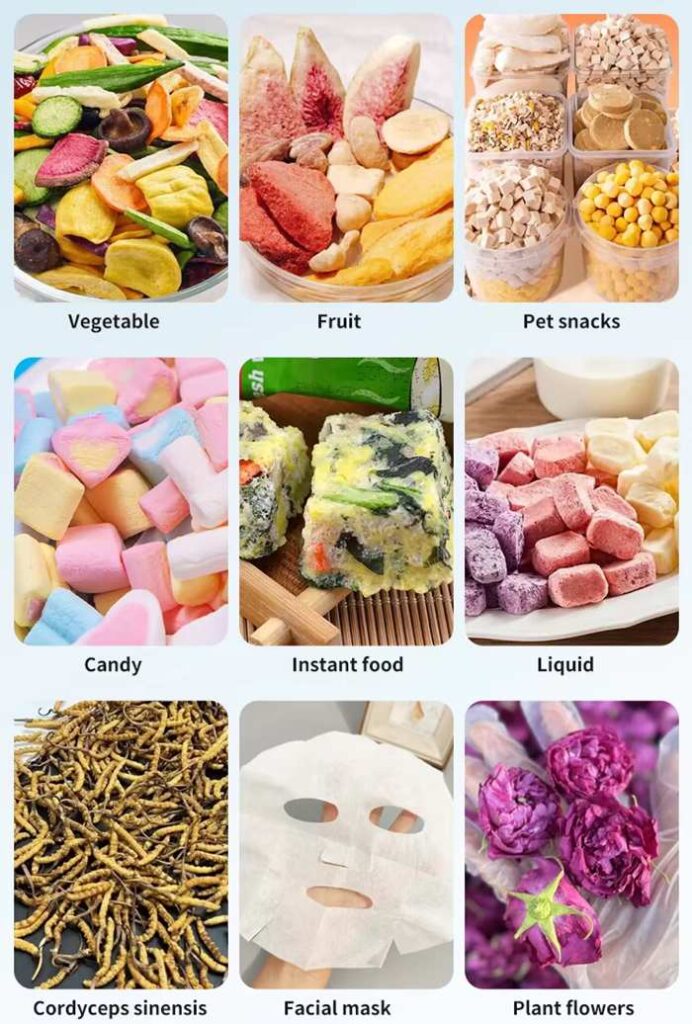

- Versatility: Ideal for fruits, meats, dairy, full meals—even candy!

- Ease of Use: One-touch automatic operation.

- Cost Savings: DIY freeze drying is cheaper than store-bought alternatives.

Key Components of a Freeze Dryer

- Vacuum Chamber: Creates low-pressure environment for sublimation.

- Condenser: Freezes and captures moisture as vapor.

- Shelves: Hold products, regulate temperature, and ensure even drying.

Freeze Drying in 3 Stages

- Freezing Stage: Material is rapidly frozen at -50°C or lower.

- Primary Drying Stage: Vacuum pump causes sublimation of ice crystals.

- Secondary Drying Stage: Removes bound moisture to finish the drying cycle.

Industries That Use Commercial Freeze Dryers

- R&D Labs: Sample testing and product development.

- Food & Beverage: Fruits, vegetables, meals, and snacks.

- Pet Food: Treats, full meals, chews, and supplements.

- Pharma & Biotech: Stabilized compounds for research and drug development.

- Cosmetics & Skincare: Preserved formulations and ingredients.

- Gardening: Long-term preservation of homegrown produce.

- Emergency Prep: Lightweight, long-lasting food for survival kits.

Why Buy From Foodline?

- Affordable Solutions: Scale up with multiple units at a fraction of industrial costs.

- User-Friendly Design: No expert operation needed—just press start.

- Premium Results: Superior product quality compared to other commercial freeze dryers.

- Reliable Support: From setup to maintenance, we’ve got your back.

📞 Contact Us for a Quote

Ready to take your production to the next level? Whether you need a compact commercial freeze dryer for a lab or high-volume machines for food processing, Foodline has the perfect solution.

👉 Contact us now for pricing, customization, and support.