The commercial brine injector machine is a solution for precise brine and curing injection. Whether you’re curing ham, marinating chicken, or preparing deli cuts, this machine ensures consistent taste, tenderness, and production efficiency.

Technical Parameters of Meat Curing & Flavoring Equipment

| Model | FL-8 | FL-48 | FL-60 | FL-80 | FL-120 | FL-160 |

| Needlesnumber(pcs) | 8 | 48 | 60 | 80 | 120 | 160 |

| Needles diameter(mm) | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Power(kw) | 0.75 | 4.1 | 4.1 | 4.8 | 4.8 | 7 |

| Injection time(times/min) | / | 36 | 36 | 36 | 36 | 36 |

| Walking speed(m/min) | / | 2.59 | 2.59 | 2.59 | 3.5 | 2.59 |

| Injection pressure(mpa) | / | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 |

| Voltage(V) | 220 | 380 | 380 | 380 | 380 | 380 |

| Size(mm) | 1340*730*740 | 960*1350*1750 | 960*1350*1750 | 960*1350*1750 | 1160*1650*1760 | 960*1860*1760 |

| Weight(kg) | 54 | 250 | 320 | 340 | 400 | 520 |

Commercial Brine Injector Machine

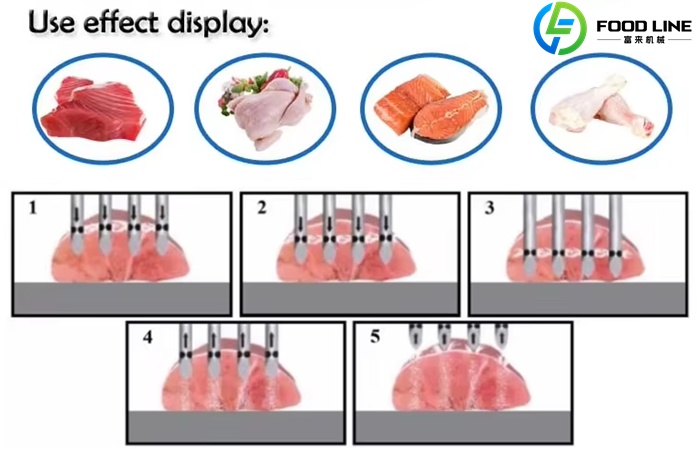

The brine injector machine is used to inject a precisely measured amount of brine, marinade, or curing solution directly into meat products using multiple injection needles. It’s widely used in poultry, pork, beef, and seafood processing to enhance flavor, moisture retention, and shelf life.

Key Features of the Brine Injector Machine

- Stainless Steel Body: Made from food-grade SUS304 for hygiene and corrosion resistance.

- Multi-Needle System: Stainless steel needles inject brine uniformly throughout the product.

- Adjustable Injection Pressure: Set based on meat type and recipe requirements.

- Conveyor Belt Feeding: Continuous operation for high-volume processing.

- Self-Cleaning System: Easy needle cleaning and automatic rinsing between batches.

- Brine Filtering System: Recycles brine while removing residue or bone particles.

What Can You Inject with This Machine?

This equipment is perfect for various meat and seafood items:

| Product Type | Examples |

|---|---|

| Poultry | Chicken breast, wings, turkey |

| Beef | Brisket, steak, pastrami |

| Pork | Ham, bacon, pork loin |

| Seafood | Fish fillets, squid, surimi |

| Plant-Based Meats | Tofu, seitan, soy protein |

Whether you run a meat processing plant, poultry facility, or ready-to-eat food factory, this machine is designed for high-efficiency flavoring and curing operations.

FAQs About Brine Injector Machines

How does a brine injector differ from a tumbler?

A brine injector directly injects liquid into the muscle fibers using needles, while a tumbler uses vacuum and rotation to absorb the marinade.

Can I control how deep the needles go?

Yes! Most machines allow adjustable needle depth and pressure for delicate or thick cuts.

Is it safe for bone-in products?

Yes, many models include spring-loaded needles or pressure adjustments to avoid breakage when hitting bones.

How do I clean the machine?

Brine injectors come with CIP (Clean-in-Place) systems and quick-release needles for easy sanitation.

Why Choose Our Commercial Brine Injector?

- Exported to 40+ countries

- Custom-built to fit your production line

- On-site installation and tech support available

- High yield, high ROI, long service life

Contact Us Today for a Quote

Need a reliable and efficient meat brine injector machine for your business?

We offer factory-direct prices, OEM services, and global shipping.