As the food industry continues to move towards intelligence and automation, fully automatic pizza making machine production lines have emerged.

Fully automatic pizza making machine | Production line

The fully automatic commercial pizza making equipment is a set of assembly line equipment that integrates dough mixing, proofing, pressing, shaping, spreading, sprinkling, baking, cooling and packaging. It is designed to mass-produce various frozen pizzas or freshly baked pizzas in large quantities and with high efficiency.

Technical parameters of automatic pizza maker

| Machine | Machine Dimension (cm) | Machine Weight | Voltage | Power | Capacity | Product Weight |

| Dough Pressing Machine | 157 × 109 × 150 | 650 KG | 380V | 3.29 KW | 80–150 pcs/min | 10–150 g |

| Dough Divider Machine | 165 × 61 × 131 | 210 KG | Single Phase 220V | 0.52 KW | ||

| Main Bread Machine | 450 × 66 × 168 | 375 KG | 380V | 2.5 KW | ||

| Filling Machine | 66 × 75 × 146 | 85 KG | Single Phase 220V | 0.5 KW | ||

| Pinching Cutter Machine | 52 × 86.5 × 81 | 135 KG | Single Phase 220V | 0.5 KW | ||

| Dough Rolling Machine | 170.6 × 83.3 × 133.4 | 300 KG | Single Phase 220V | 0.6 KW | ||

| Auto Arranging Machine | 185 × 156 × 164 | 320 KG | Single Phase 220V | 1.5 KW |

9 pieces of equipment in pizza production line

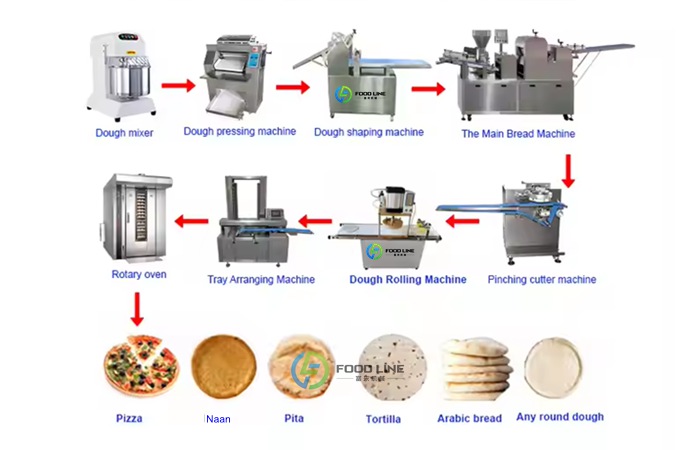

The fully automatic pizza production line usually includes the following core parts:

- Dough Pressing Machine: Flattens the raw dough into a consistent round or oval pizza base;

- Dough Divider Machine: Cuts a large batch of dough into equal portions based on weight;

- Main Bread Machine: Performs the core forming and shaping of the pizza base;

- Filling Machine: Automatically dispenses sauces, cheese, and other toppings onto the dough base;

- Pinching Cutter Machine: Cuts or crimps the pizza dough (for stuffed crusts or patterned edges).

- Dough Rolling Machine: Rolls dough balls into flat, even discs with smooth surfaces;

- Auto Arranging Machine: Automatically arranges the finished pizzas onto trays or conveyor belts

- Tunnel oven for baking: High temperature and uniform baking of pizza, stable taste;

- Cooling conveyor line: Automatic packaging machine, Vacuum packaging or frozen packaging after rapid cooling.

Why you should invest this commercial pizza making machine?

- High efficiency: The whole process is automatically controlled, and the output can reach 1,000 to 3,000 pizzas per hour.

- High consistency: Each pizza has uniform specifications to ensure consistent taste.

- Labor saving: Only a small number of personnel are required to monitor, which greatly reduces labor costs.

- High hygiene standards: The equipment is made of food-grade stainless steel, easy to clean, and complies with HACCP, ISO and other certifications.

- Flexible and adjustable: The size of the dough, the distribution of the sauce, and the amount of ingredients can be adjusted programmably to meet various production needs.

Upgrade to Automation – Request a Free Quote!

What kind of pizzas this production line can produce?

This pizza production line is suitable for the automated production of various types of pizza, such as: traditional Italian pizza, American thick crust pizza, frozen ready-to-eat pizza, vegetarian pizza / meat pizza, customized pizza (size and ingredients can be adjusted as needed), etc.

Customer Case – FoodLine automated pizza making machine

A frozen food company from Saudi Arabia tripled its production capacity after introducing a fully automatic pizza production line provided by FoodLine Machinery. The head of the company said:

“We used to make a maximum of 500 pizzas a day, but now we can easily make 2,000 pizzas a day, and the size, thickness and ingredients are consistent, and customer satisfaction has skyrocketed.”

Conclusion

Fully automatic pizza production line is an inevitable trend in the future development of the food industry. Whether you are an established company looking to expand production capacity or a new factory under construction, it can bring you a double leap in quality and quantity.

If you need a quote, parameter configuration or video demonstration, please contact us to get a full set of pizza production line information package.

📞 Contact Foodline Machinery now 📩 Leave your messages here to get a quote