Are you looking to start or upgrade your instant noodle production? Whether you’re running a food processing company, snack manufacturer, institutional kitchen, or private-label brand, the Foodline Instant Noodle Production Line helps you produce premium-quality noodles efficiently, hygienically, and profitably — all in one streamlined system.

Specifications of Steam fried instant noodle production line

| Model | FL-250 | FL-260 | FL-350 |

| Voltage | 380V/50hz | 380V/50hz | 380V/50hz |

| Power (kw) | 120 | 40 | 54 |

| Steam consumption (kg/h) | – | 900-1100 | 1100-1300 |

| Noodle belt width (mm) | 250 | 260 | 350 |

| Labor needed | 3 | 4 | 4 |

| Capacity | 11000bags/8hours | 30000bags/8hours | 60000bags/8hours |

| Factory size (m) | 26×6×4.5 | 60×6×4.5 | 76×8×4.5 |

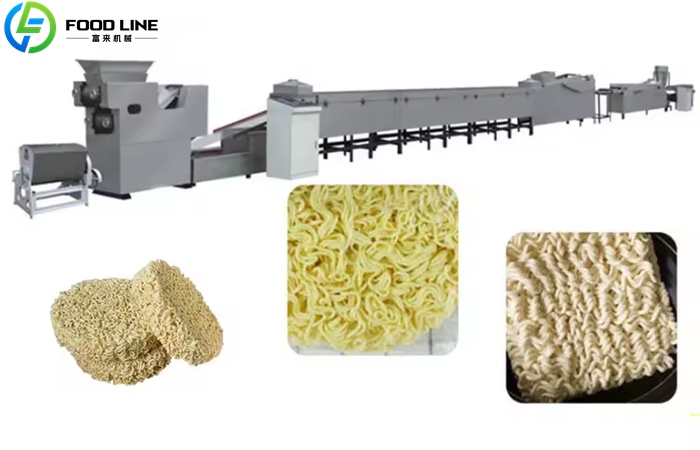

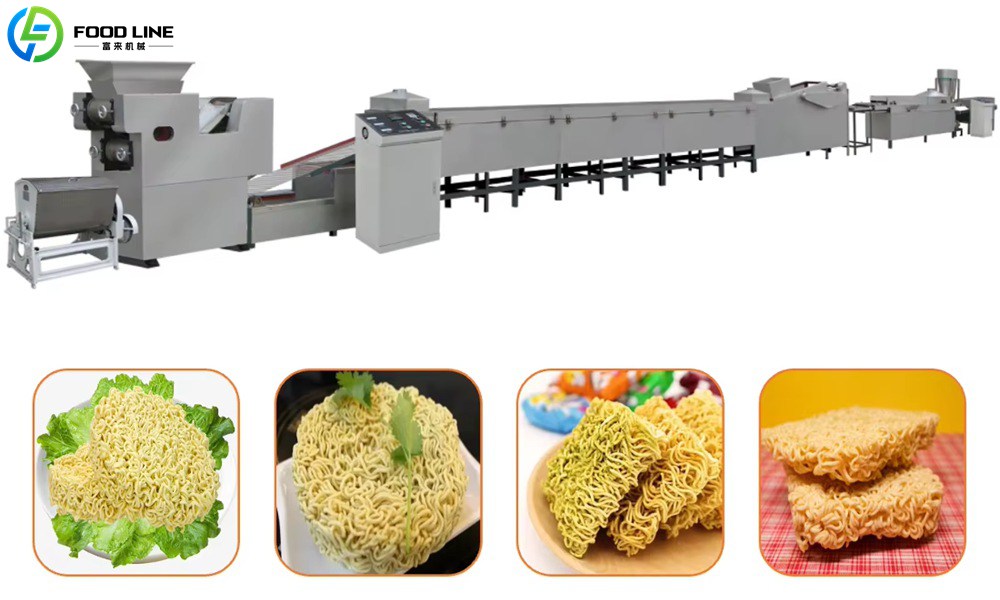

Foodline Instant Noodle Production Line

The Instant Noodle Production Line is a fully automated system designed to produce fried or non-fried instant noodles with consistent texture, perfect shape, and long shelf life.

Production Process Overview:

- Dough Mixing

- Rolling & Cutting

- Steaming

- Cutting & Folding

- Frying or Air-Drying

- Cooling

- Packaging

💡 One line, endless possibilities — cup noodles, bag noodles, or custom noodle shapes.

Main Components of Foodline Instant Noodle Making Machine

| Machine Component | Function | Key Features |

|---|---|---|

| Flour Mixer | Mixes raw ingredients | Stainless steel body, automatic water dosing |

| Dough Compound & Roller | Forms dough sheet | Adjustable thickness, uniform texture |

| Slitter & Waving Device | Cuts noodles & forms wave shape | Precision cutting blades |

| Steaming Conveyor | Cooks noodles | Automatic temperature control |

| Cutting & Folding Unit | Shapes noodle blocks | Consistent block weight and size |

| Frying Machine | Dehydrates noodles | Energy-efficient oil circulation |

| Cooling System | Cools noodles before packaging | Ensures food safety and crispness |

| Packaging Machine | Packs noodle blocks | Compatible with pillow or cup-style packaging |

Customer Success Story: Foodline Instant Noodle Line in Indonesia

One of our clients from Surabaya, Indonesia recently installed a Foodline 10,000-packs/day instant noodle line. The customer aimed to enter the affordable snack market with local flavors like chicken, curry, and seafood.

“Foodline helped us set up the entire noodle plant — from layout design to on-site commissioning. The production line runs smoothly, and our noodles get excellent feedback from customers!”

— Mr. Yusuf, Factory Manager, Indonesia

Limited-Time Offer! Contact us today to get a discount! WhatsApp/Tel 008613598866720

FAQs about Foodline Instant Noodle Production Line

1. Can the machine produce both fried and non-fried noodles?

Yes! Foodline offers dual-system designs — you can choose oil-frying for crispy instant noodles or air-drying for healthier versions.

2. What raw materials are suitable?

High-gluten wheat flour, starch, water, and seasonings are commonly used. The line can adapt to different regional recipes.

3. How long is the installation period?

Usually, 15–30 days, depending on the plant layout and model size. Foodline engineers provide on-site or remote installation guidance.

4. Do you provide recipe formulation support?

Yes! Our food technologists help clients fine-tune noodle texture, color, and flavor based on local market preferences.

5. What is the warranty period?

All Foodline instant noodle lines come with a 12-month warranty and lifetime technical support.