The beer can filling machine is a piece of equipment designed to automatically fill beer (or other carbonated beverages) into cans in a clean, consistent, and efficient way.

Take your craft to the next level – choose Foodline for dependable beer canning solutions.

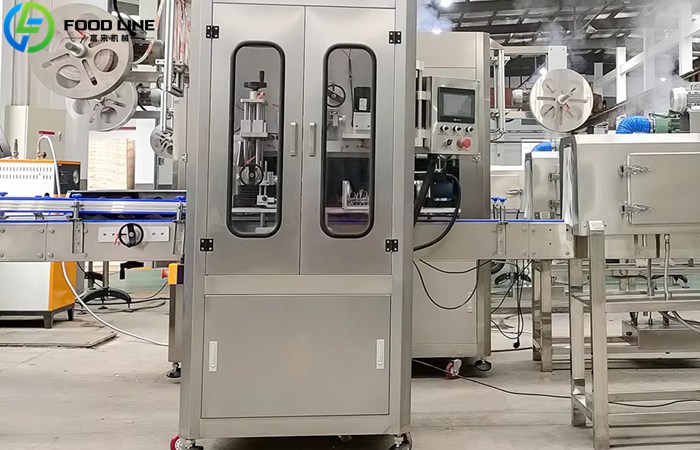

Specifications of Beer Can Filling Machine

| Model | FL18-6 | FL32-6 | FL36-6 | FL40-8 |

| Capacity | 4000-6000CPH | 10000-12000 CPH | 12000-15000 CPH | 15000-20000 CPH |

| Can Volume | 200ml-1000ml | 200ml-1000ml | 200ml-1000ml | 200ml-1000ml |

| Can diameater | 50-70mm | 50-70mm | 50-70mm | 50-70mm |

| Bottle high | 120-170mm | 120-170mm | 120-170mm | 120-170mm |

| Machine power | 3.5KW | 5.5KW | 7.5KW | 9.5KW |

| Machine size | 175x120x195CM | 305x175x220CM | 340X195X220CM | 350x235x225CM |

What Beer Can Packing Machine Does?

- Fills cans with beer: The machine measures a precise amount of beer and transfers it into empty cans.

- Controls carbonation and foam: Special filling valves keep CO₂ in the liquid and reduce oxygen pickup, which preserves freshness and flavor.

- Prepares for sealing: After filling, cans move to a can seamer where lids are sealed tightly to protect the contents.

Applications of Can Filler Filling Machine

- Craft beer and lager

- Hard seltzer and RTD cocktails

- Cider, kombucha, and other carbonated drinks

Ideal for microbreweries, co-packing facilities, and beverage R&D labs.

How to Choose the Right Beer Can Filling Machine

When selecting a beer canning machine, consider:

- Your daily or monthly production volume

- Can sizes (e.g., 200ml, 330ml, 500ml)

- Carbonation levels of your product

- Available space and utilities (water, CO₂, compressed air)

- Whether you need an inline or rotary filler

Foodline’s experts can evaluate your production goals and recommend the most cost-effective solution.

FAQs About Beer Can Filling Machines

1. What is the average cost of a beer can filling machine?

Prices vary based on capacity and features.

2. Can the Foodline machine handle beverages other than beer?

Yes! It’s suitable for carbonated drinks like cider, hard seltzer, kombucha, soda, and energy drinks.

3. How do I maintain the machine?

Routine cleaning with CIP (clean-in-place) systems, regular lubrication of moving parts, and periodic seal inspection keep the filler in optimal condition.

4. Is operator training available?

Absolutely. Foodline provides detailed manuals, video tutorials, and remote or on-site training.

Why Partner With Foodline?

Foodline has over 20 years of experience in beverage processing machinery. Our solutions are trusted by breweries worldwide for their durability, precision, and after-sales support. We also offer installation guidance, spare parts, and lifetime technical assistance.