Upgrade your pet food production with our reliable dog food extruder. Whether you’re just starting out or have years of experience, this machine helps you produce high-quality dry dog food efficiently and consistently. Built to handle a wide range of ingredients, it’s a practical choice for growing your pet food business.

Technical Specifications of pet food extruder machine

| Model | Main Power(KW) | Capacity(T/H) |

| FL55 | 22 | 0.15-0.3 |

| FL65 | 45 | 0.1-0.3 |

| FL68 | 75 | 0.5-1.3 |

| FL98 | 110/132 | 1.5-3.0 |

| FL130 | 200/160 | 3.0-6.0 |

| FL138 | 250/200 | 5.0-8.0 |

| FL158 | 400/355 | 8.0-13.0 |

| FL178 | 500/630 | 13.0-20.0 |

| FL1218 | 630/800 | 20.2-25.0 |

Key Features of Dog Food Extruder Machine

Our extruders are engineered for precision, durability, and easy operation. From mixing and cooking to shaping and drying, the machine completes the full process in one smooth flow.

- Fully automatic or semi-automatic operation

- High-capacity extrusion (50kg/h – 1000kg/h options)

- Touchscreen PLC control system

- Stainless steel build for hygiene and longevity

- Multi-shape die options (bone, fish, round, heart-shaped kibble)

- Supports both dry and semi-moist formulas

Applications of Dog Food Extruder

The machine can produce a wide variety of pet foods:

| Pet Type | Output Example | Shape Options |

|---|---|---|

| Dogs | Dry dog kibble | Bone, round, fish |

| Cats | Crunchy cat food | Heart, star, pillow |

| Fish | Floating or sinking feed | Pellet, ring |

| Small animals | Rabbit or bird food | Custom shapes |

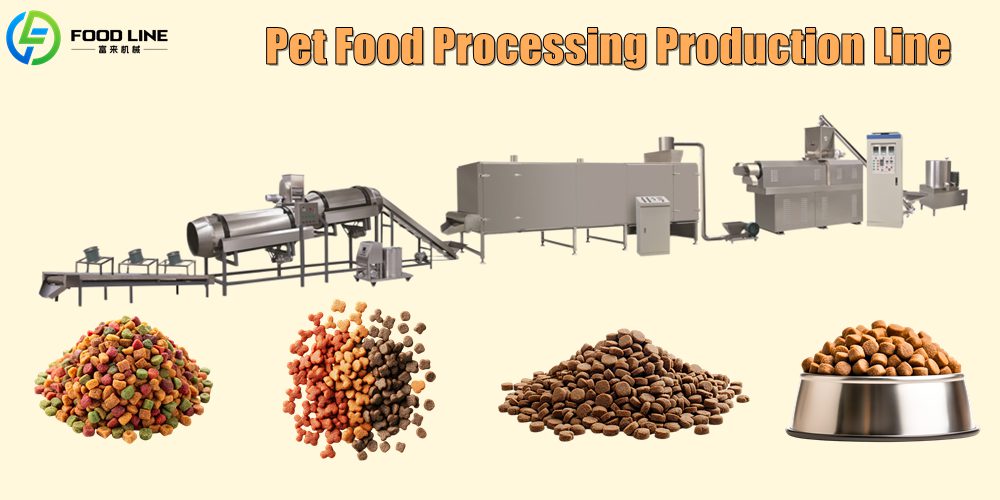

Dog Food Extruder Machine Working Process

The complete extrusion line typically includes:

- Mixer – Combine raw materials like corn, soybean meal, meat powder

- Screw Conveyor – Feed the mix into the extruder

- Extruder – High-temperature and pressure cooking with shape extrusion

- Dryer – Remove moisture for shelf-stable food

- Flavoring Machine – Add oil, vitamins, or flavor coatings

- Cooling Conveyor & Packing System

🔄 Optional Add-ons: Vacuum coating machine, automatic weighing & bagging

Raw Materials Used

- Corn, wheat flour, rice

- Fish meal, meat powder, bone meal

- Soybean meal, sunflower cake

- Vitamins, minerals, flavor enhancers

Supports both grain-based and grain-free recipes!

📞 Get a free quote now with machine video, specification sheet, and customization options. WhatsApp/Tel 008613598866720

Our Global Clients Love It

A client from South Africa recently upgraded his small-scale dog food plant using our FL-68 extruder. Within 3 months, his sales doubled, thanks to consistent kibble quality and better nutrition control.

Another customer from Brazil switched from manual pellet production to our automatic extrusion line—and now supplies over 15 pet stores!

Frequently Asked Questions (FAQs)

1. What ingredients can the dog food extruder use?

It supports a wide range including grains, fish/meat meals, vegetable powder, and nutritional additives.

2. Can I change the kibble shape and size?

Yes! Just switch the extrusion mold—bone, fish, round, star, etc. are available.

3. Is this suitable for a small business or large factory?

We offer models for both small-scale and industrial-scale production.

4. How do I maintain the machine?

Regular cleaning of the barrel and dies, lubrication of bearings, and inspection of wear parts keep the extruder in top shape.

About Us – Henan Foodline Machinery

We are a trusted pet food machinery manufacturer with 20+ years of experience exporting to over 70 countries. Our machines are CE-certified and backed by 24/7 technical support, installation guidance, and training.

Dominate the pet food market with high-efficiency extrusion.

📩 Inquire now and get your customized dog food extruder line today!