Are you looking to scale up your craft brewery or small beverage business without breaking the bank? Our semi-automatic beer bottle filling machine is the perfect solution for entrepreneurs and brewers who want precision filling without the complexity or cost of a fully automatic system.

Whether you’re running a microbrewery, launching a boutique beer brand, or expanding a small beverage line, this machine offers the perfect blend of manual control and automated efficiency.

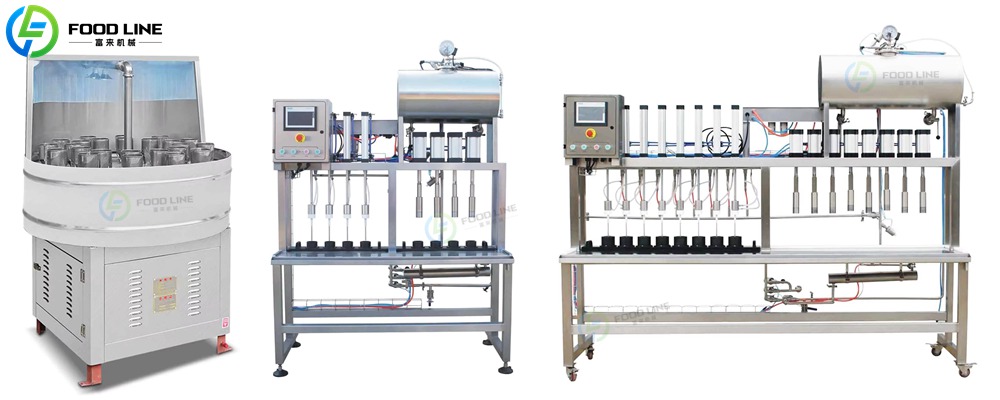

Small Scale Beer Bottling Equipment

Semi-automatic filling machines are ideal for:

- Small and medium-scale breweries

- Craft beer startups

- Pilot brewing plants

- Seasonal or limited-edition beer bottling

Specifications of Semi-Automatic Beer Bottle Filling Machine

| Model | FLSA-300 Beer Bottling Line |

| Capacity | 200-500 bottles/h |

| filling heads | 4/6/8/10 heads |

| Bottle type | Diameter 50-80MM glass bottle (customized) |

| Bottle height | 160-320MM |

| Filling capacity | 150-750ML |

| Weight | 320KG |

Features of Foodline Semi-Automatic Beer Bottling Machine

- Simple operation and easy to use: Equipped with a button or pedal control system, no professional training is required, and staff can master the operation process in a short time.

- Accurate filling and less foam: Quantitative filling technology and anti-foam nozzle design are used to effectively control the liquid level and reduce beer overflow and foam generation.

- Adapt to a variety of bottle types and capacities: Support glass bottles and plastic bottles of different specifications such as 330ml, 500ml, 1L, etc., and the bottle height and bottle diameter can be flexibly adjusted.

- The material of the equipment is hygienic and safe: The liquid contact part is made of food-grade SUS304 stainless steel, which is corrosion-resistant, easy to clean, and meets food hygiene standards.

- Support carbonated beverage filling: Optional CO₂ back pressure system, suitable for carbonated beer, to maintain beer bubbles and taste during filling.

- Compact structure and small footprint: The overall design is reasonable and does not take up space, suitable for small breweries, craft workshops or start-up beverage companies.

- Easy maintenance and stable operation: Standardized parts and modular design, easy maintenance, durable equipment, suitable for long-term use.

How small beer bottling line works?

- Place the bottles under the nozzles manually.

- Activate the filling valve using the foot pedal or button.

- The machine fills each bottle with precise control and minimal foaming.

- Move bottles to the capping station (manual or semi-auto capper available).

- Done—your beer is ready for labeling and packaging!

Advantages of a Semi-Automatic Beer Filling Machine

- Time-Saving: Faster than hand-filling, ideal for small batch production.

- Cost-Effective: Lower investment than fully automatic lines.

- Easy Maintenance: Simple construction, easy cleaning.

- Flexible Bottling: Accommodates various bottle types and sizes.

- Sanitary Design: Made for the food & beverage industry with hygiene in mind.

Applications

Our semi-automatic beer bottling machines are suitable for:

- Craft beer

- Kombucha

- Soda & sparkling water

- Cold brew coffee

- Wine, cider, and mead (optional upgrades)

You may also like: Automatic Beer Bottling Machine For Sale

Global Shipping & Customization Available

We serve clients worldwide, from the USA, Canada, and the UK to Southeast Asia, Africa, and beyond. Custom configurations, OEM branding, and voltage adjustments are available upon request.

Real-Life Use Case: A Microbrewery in Australia

A microbrewery in Melbourne recently upgraded to our semi-automatic beer bottle filler to meet rising demand. With a 500 BPH model, they doubled their daily output and reduced filling errors by 80%. Plus, they appreciated the machine’s simple installation and low learning curve for their small team.

Ready to Scale Your Brewery?

Upgrade your bottling process with a reliable semi-automatic beer bottle filling machine.

FAQs About Semi-Automatic Beer Bottle Filling Machines

Q1: How fast is a semi-automatic beer filling machine?

A: Speed ranges from 200 to 500 bottles per hour depending on the number of heads and operator efficiency.

Q2: Can I fill carbonated beer with this machine?

A: Yes! Choose a model with CO₂ back pressure filling to preserve carbonation.

Q3: Is it easy to clean the machine?

A: Absolutely. Most models include CIP-compatible parts and can be quickly disassembled for deep cleaning.

Q4: What bottle sizes can it fill?

A: It supports multiple sizes—standard 330ml, 500ml, and 1L bottles.

Q5: Can I use this for other drinks besides beer?

A: Yes, it’s great for kombucha, soda, cold brew, cider, and more.