In today’s food industry, cleanliness and efficiency matter more than ever. That’s why more potato processors, farms, and food factories are turning to automated machines to keep their products clean and consistent. One key machine in this process is the potato washing machine.

Foodline Potato Washing Machine

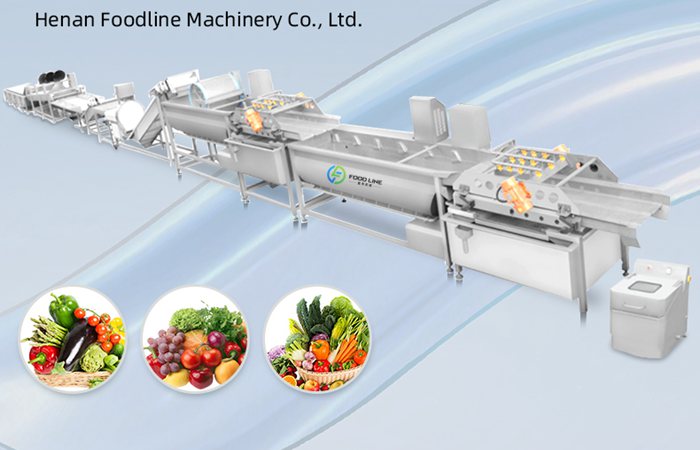

The Foodline Potato Washing Machine is an automated cleaning machine that removes soil, dirt, and debris from potatoes with minimal water usage and maximum efficiency. It features a durable stainless-steel body, soft rotary brushes, and a high-pressure water system that ensures thorough yet gentle washing.

This machine is designed for commercial and industrial-scale operations. It can handle large quantities of potatoes per hour, making it ideal for:

- Potato chip factories

- French fry processing lines

- Agricultural cooperatives

- Vegetable wholesale operations

- Central kitchens and food prep facilities

Features of the Foodline Potato Washing Machine

✅ High-Capacity Output

The machine is engineered to process hundreds of kilograms of potatoes per hour, making it a great fit for busy operations that need to scale their washing process without increasing labor.

✅ Gentle but Effective Washing

Using rotating nylon brushes and water spray nozzles, the machine removes mud and impurities from the potato surface while protecting the skin from damage. This is crucial for processors looking to maintain the appearance and integrity of fresh produce.

✅ Stainless Steel Construction

Made from food-grade 304 stainless steel, the machine resists corrosion and meets food hygiene standards. It’s easy to clean, durable, and built to last in demanding production environments.

✅ Adjustable Washing Time

Operators can adjust the washing time and water flow to suit different types of potatoes or cleaning requirements, whether for lightly soiled baby potatoes or muddy harvest batches.

✅ Easy Maintenance and Operation

With a user-friendly control panel, quick-disassembly parts, and accessible cleaning points, maintenance is fast and straightforward—reducing downtime and keeping your line moving.

Why Invest in a Potato Washing Machine?

1. Labor Savings

Automating the washing process can drastically cut down on manual labor, reducing overhead costs while improving consistency.

2. Water Efficiency

The Foodline machine uses recyclable water systems, helping companies lower water usage while maintaining high hygiene standards.

3. Product Consistency

Manual washing can vary in quality. A machine ensures every batch is uniformly cleaned, which is essential for downstream slicing, frying, or packaging.

4. Compliance with Food Safety Regulations

Maintaining cleanliness is non-negotiable. This machine helps processors comply with HACCP and food safety standards more easily.

Who Should Buy the Foodline Potato Washing Machine?

This machine is ideal for:

- Startups and small factories looking to scale operations efficiently

- Large-scale manufacturers who want to optimize throughput

- Exporters and suppliers needing consistent, clean produce

- Agricultural cooperatives managing bulk harvests

- Vegetable processing lines needing equipment that integrates seamlessly with peeling and slicing machines

Integration with Other Machines

The Foodline Potato Washing Machine can be paired with:

- Potato peeling machines

- Potato cutting machines

- Fryers or blanchers

- Sorting and packaging equipment

It’s often the first step in a complete potato processing line, ensuring that only clean, debris-free tubers move forward in production.

Customer Testimonials

“We’ve been using the Foodline potato washer for over a year—it has dramatically improved our cleaning process and helped us cut labor in half.”

— Carlos M., Potato Chip Factory Owner

“The machine pays for itself with the time it saves. It’s reliable, easy to clean, and perfectly fits our processing line.”

— Sunita R., Frozen French Fry Exporter

Ready to upgrade your potato washing process?

Contact us today to get a quote on the Foodline Potato Washing Machine and take the first step toward cleaner, more efficient production