Launching a snack factory can be one of the most profitable—and low-risk—business opportunities in the food industry today. Whether your goal is to produce potato chips, popcorn, tortillas, nuts, puffed snacks, or extruded snacks, the key to success is simple:

👉 Choose the right machines, build an efficient production line, and keep your operating cost low.

This guide breaks down everything you need to start a snack production line, including core equipment, cost ranges, workflow design, raw materials, and layout suggestions.

Let’s get into it.

1. What Counts as a “Snack Factory”?

A snack factory is any food-production setup designed to produce packaged snacks at scale. Common factory types include:

- Potato chips factory

- Tortilla chips factory

- Popcorn factory

- Puffed snack / extruded snack factory

- Nut roasting and packaging plant

- Banana chips factory

- Corn tortilla factory

- Mixed snack processing plant

The machinery varies, but the production flow is similar: raw materials → processing → frying/roasting → seasoning → packaging.

2. Essential Machines Needed for Snack Production

Below is the complete machine list used in most snack factories. Your exact setup depends on the snacks you plan to produce.

(1) Washing & Peeling Machines

Used for potato chips, banana chips, cassava chips, and vegetable snacks.

Typical machines:

- Automatic potato washing machine

- Commercial peeler

- Brush roller washer

(2) Slicing, Shredding & Cutting Machines

Used for:

- Potato chips

- Tortilla chips

- Fruit & vegetable snacks

Available options:

- Potato slicer (wave or flat cut)

- Vegetable cutter

- Multi-functional dicer

(3) Frying Machines or Roasting Machines

This step is the “heart” of most snack factories.

For fried snacks:

- Continuous fryer

- Batch fryer

- Oil filter system

- Oil conveyor

For roasted snacks:

- Drum roaster

- Nut roasting machine

- Hot air oven

(4) De-oiling & Cooling Machines

After frying or roasting, snacks must be de-oiled or cooled:

- De-oil machine (centrifugal)

- Cooling conveyor

- Air-cooled tunnel

Purpose: Improve taste, texture, and oil control.

(5) Flavoring & Seasoning Machines

Used for all snack types.

Options include:

- Octagonal seasoning drum

- Continuous seasoning line

- Powder feeder

Why it’s important: Seasoning consistency determines product quality—and customer satisfaction.

(6) Automatic Packaging Machines

Packaging is where profits become real.

Machines include:

- Vertical form fill seal (VFFS) packing machine

- Multi-head weigher

- Nitrogen-flushing system for freshness

- Pillow packing machine

- Gusset bag packing machine

This is the machine category buyers underestimate—but it’s critical for shelf life and branding.

3. Snack Factory Layout (Simple Overview)

A typical medium-size snack production line looks like this:

Raw materials → Washing & peeling → Slicing / cutting → Frying or roasting → De-oiling / cooling → Seasoning → Packaging → Finished products

4. Cost Breakdown: How Much Does It Take to Start a Snack Factory?

Here’s an estimated investment range depending on size:

Small factory (500–1,000 kg/day)

- Machines: $8,000–$25,000

- Space: 80–150 m²

- Workers: 2–4

Medium factory (2,000–5,000 kg/day)

- Machines: $25,000–$80,000

- Space: 200–500 m²

- Workers: 5–10

Large factory (10,000 kg/day+)

- Machines: $80,000–$300,000+

- Custom solutions available

Price varies depending on:

- Product type

- Capacity

- Full automation vs semi-automatic

- Stainless steel grade

- Packaging type

If you need a specific quote, pls click the button below to get a free quote.

5. Choosing the Right Snack Machines: What to Look For

When purchasing equipment, focus on:

- Food-grade stainless steel

- Reliable heating system

- Easy-to-clean design

- CE or ISO certifications

- Energy-efficient motors & burners

- Customizable production line layout

A well-designed machine can reduce oil consumption by 30% and energy by 15%, saving thousands yearly.

6. Common Snack Factory Types (with Recommended Machines)

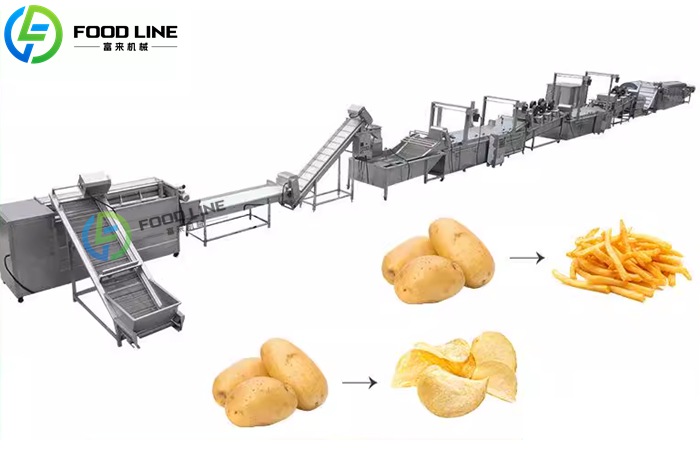

1. Potato Chips Factory

- Packaging machine

- Potato washer

- Peeler

- Slicer

- Continuous fryer

- Conveyor

- Seasoning drum

2. Tortilla Chips Factory

- Corn mixing system

- Press machine

- Baking oven

- Frying line

- Seasoning system

- Packaging machine

3. Popcorn Factory

- Popcorn popping machine

- Caramel coating system

- Cooling table

- Packaging machine

4. Nut Roasting Factory

- Roasting oven

- Cooling conveyor

- Seasoning drum

- Weighing & packing machine

Limited-Time Offer! Contact us today to get a discount! WhatsApp/Tel 008613598866720

7. Profit Potential: How Much Can a Snack Factory Earn?

Snack production has one of the highest profit margins in food manufacturing.

Average numbers:

- Raw materials: Cheap (corn, potatoes, flavorings)

- Selling price: High, especially packaged retail snacks

- Gross profit margin: 25%–45%

- ROI: Often achieved in 3–12 months

If you distribute to supermarkets or online channels, profits grow even more.

8. Why More Buyers Choose Foodline Snack Machines

Foodline provides:

- Full turnkey snack factory solutions

- Factory design + workflow layout

- CE/ISO-certified machines

- High-quality stainless steel

- Worldwide shipping

- One-on-one engineering support

- Free installation guide

Whether you’re launching a small workshop or a full-scale industrial plant, Foodline can build the production line that fits your budget and product.