AI cherry tomato vision sorting robot is an automated system that uses computer vision and artificial intelligence to identify, grade, and separate cherry tomatoes based on size, color, ripeness, or defects.

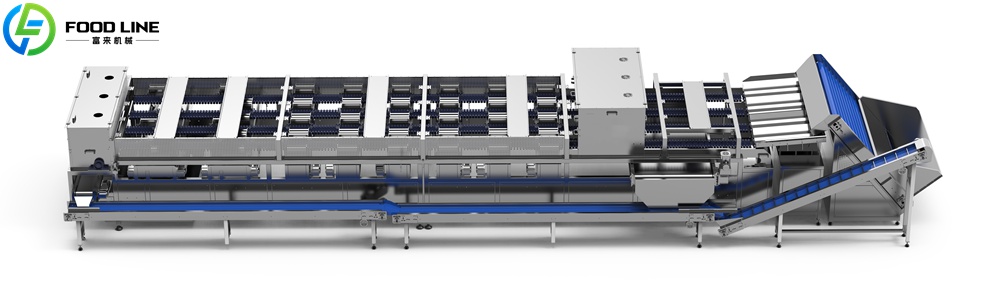

Foodline AI Cherry Tomato Vision Sorting Machine

The AI cherry tomato color sorting machine is an automated grader that uses computer vision and artificial intelligence to detect ripeness, size, and surface quality. Equipped with high-speed cameras and precise sorting arms or air jets, it can handle thousands of tomatoes per hour without bruising them.

Specifications of Tomato Sorting Machine

| Equipment Model | Output (Based on GB/T26150 Grade 1 Red Dates, includes defects & finished product) | Export Quantity |

|---|---|---|

| FL-CC6T-V8 | 800~1200 kg/hour | 8 |

| FL-CC8T-V8 | 1100~1500 kg/hour | 8 |

| FL-CC10T-V8 | 1500~1800 kg/hour | 8 |

| FL-CC12T-V8 | 1500~1800 kg/hour | 8 |

| FL-CC16T-V8 | 1500~1800 kg/hour | 8 |

Features of tomato grading machine

- Performs non-destructive testing, detecting defects such as external blemishes and internal decay.

- High-speed sorting, with throughput reaching 800-1800 kg/hour, depending on the model.

- One-click sorting, multi-dimensional optimization, and simple operation significantly improve sorting speed.

- Complete multiple tasks in one sorting operation, reducing process steps.

- Non-destructive testing reduces the loss of high-quality fruit.

- Equipped with an advanced visual recognition system.

- The tomato sorting machine can be customized according to specific customer needs, flexibly adapting to different production lines.

- Compatible with fruit and vegetable processing lines of all sizes, it has a wide range of application scenarios.

- User-friendly interface, easy to learn and operate.

Limited-Time Offer! Contact us today to get a discount! WhatsApp/Tel 008613598866720

How It Works?

Feeding & Alignment

Tomatoes travel along a gentle conveyor that separates and positions each fruit.

360° Image Capture

Multi-angle cameras take high-resolution shots of every tomato.

AI Analysis

Deep-learning algorithms evaluate:

- Ripeness (color spectrum from green to red)

- Diameter and roundness

- Defects such as bruises, cracks, rot, or insect damage

Grading & Sorting

According to the parameters you set (e.g., “Premium,” “Grade B,” “Reject”), soft grippers or air jets guide tomatoes into different bins.

Data Logging

Some models generate real-time reports on quantity, defect rates, and weight.

FAQs

1. Can a vision sorting robot handle other fruits?

Yes! Many systems can be trained for cherry tomatoes, grapes, cherries, small peppers, and even olives.

2. How accurate are these machines?

Depending on camera quality and AI training, accuracy often reaches 95–99%.

3. Do they damage delicate tomatoes?

Not if equipped with soft silicone grippers or air-jet sorting — perfect for maintaining skin integrity.

4. What is the price of an AI tomato color sorting machine?

Prices vary widely (USD 15,000–80,000+) based on capacity, camera specs, and automation level.

5. Is operator training difficult?

Most suppliers provide user-friendly touch screens and short training sessions.

👉 Ready to modernize your sorting line?

Explore the latest AI cherry tomato sorting robots for sale, compare specs, and request a demo from trusted suppliers to see how smart grading can elevate your business.