Do you know how we prepare apples quickly, cleanly, and consistently? If you’re in the business of fruit processing or managing a commercial kitchen, you must have the Foodline industrial apple peeler corer slicer. This all-in-one machine is designed for high-volume operations that require fast, uniform apple peeling, coring, and slicing. It is an essential investment for food manufacturers, fruit processors, bakeries, and commercial kitchens.

In this blog, we’ll dive into what makes the Foodline industrial apple peeler corer slicer a standout choice, who should consider buying it, and how it can benefit your business.

What Is the Foodline Industrial Apple Peeler Corer Slicer?

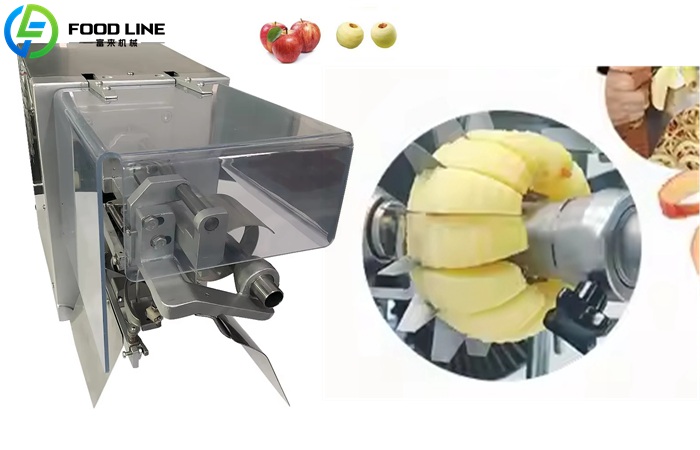

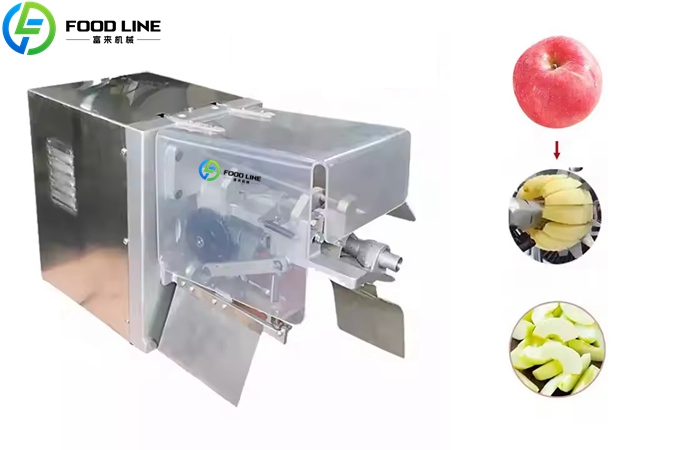

The Foodline industrial apple peeler corer slicer is a commercial-grade machine designed to automate three tasks in one seamless process—peeling, coring, and slicing apples. With a high-speed rotating mechanism and precision-engineered blades, it can handle dozens of apples per minute while maintaining excellent consistency.

| Product Name | Electric Industrial Apple Cutter Corer Slicer |

| Model | MG-AD600 |

| Maximum output | 600PCS/H [(8-10PCS/MIN), (50-60KG/H) |

| Motor Power | 180W |

| Voltage | 220V |

| Final Product | Apple segments |

| Cutting Pcs | 2, 4, 6, 8, 10,12, 16, etc |

| Apple Diameter | 50-90MM |

| G.W | 50KG |

| N.W | 40KG |

Key Features:

- 3-in-1 Functionality: Peels, cores, and slices apples in one go.

- Stainless Steel Build: Durable, food-safe, and corrosion-resistant.

- Adjustable Thickness Settings: Customize the slice thickness based on your product needs.

- Easy to Operate: User-friendly interface with simple controls.

- High Output: Ideal for industrial-scale production lines.

Who Needs This Machine?

This machine is tailored for businesses that need to process large quantities of apples quickly and efficiently. Here are some key target audiences:

1. Fruit Processing Plants

Whether you’re producing dried apples, canned fruit, or apple sauce, efficiency is crucial. This machine helps speed up production while maintaining uniform product quality.

2. Bakeries & Confectionery Producers

If your business makes apple pies, tarts, or pastries, the uniform slices from this machine ensure product consistency. Plus, the labor-saving aspect is a big win for productivity.

3. Juice and Cider Manufacturers

High volumes of apples need to be prepped for pressing. This machine simplifies the initial prep process, reducing manpower and increasing output.

4. Commercial Kitchens & Catering Services

Hotels, hospitals, school kitchens, and large-scale caterers benefit from automating apple preparation, saving both time and labor costs.

5. Farmers and Orchards

Seasonal apple harvesters looking to add value to their products through minimal processing can use this machine for fresh-cut or packaged apple products.

Why Choose Foodline?

Foodline is a trusted name in food processing machinery, known for quality engineering and robust customer support. Here’s why businesses around the world choose Foodline:

- Proven Performance: Foodline machines are built for 24/7 industrial use.

- Ease of Maintenance: Spare parts are readily available, and maintenance is straightforward.

- Global Shipping & Support: Whether you’re in North America, Europe, or Asia, Foodline ships internationally and provides excellent after-sales service.

Get a Free Quote Today! Tell us your requirements, and our expert team will respond quickly with a custom solution. WhatsApp/WeChat/Tel: 008613598866720

Benefits of the Foodline Apple Peeler Corer Slicer

1. Time-Saving Automation

Manually peeling and slicing apples can be slow and inconsistent. This machine automates the process, drastically cutting down labor time and improving speed.

2. Labor Cost Reduction

With one machine performing three tasks, businesses can reduce the number of workers needed for apple preparation, saving on labor costs.

3. Consistency and Quality Control

Manual preparation often leads to uneven slices or missed cores. Foodline’s machine ensures each apple is processed identically, improving product presentation and reducing waste.

4. Hygienic and Safe Operation

Made from stainless steel, the machine is easy to clean and meets international food safety standards. Safety features protect workers during operation.

5. Versatile Output

From thin slices for chips or pies to chunkier slices for salads and cooking, the machine offers adjustable settings to fit your needs.

How to Purchase the Foodline Apple Peeler Corer Slicer

Interested in purchasing the Foodline industrial apple peeler corer slicer? Visit [your official distributor or product page] to request a quote, download the product brochure, or talk to a sales expert.

Make sure to consider the following before purchase:

- Your production volume

- Desired slicing thickness

- Available space in your facility

- Voltage compatibility

Testimonials

“Switching to the Foodline apple corer slicer cut our prep time in half. It’s reliable, fast, and easy to clean.”

– Sarah J., Fruit Processing Plant Manager

“We use it daily in our pie production line. The consistency in slicing is excellent!”

– Martin G., Commercial Bakery Owner

Final Thoughts

The Foodline industrial apple peeler corer slicer is more than just a machine—it’s a solution. It helps fruit processing businesses reduce waste, save time, and increase efficiency with a minimal learning curve. If you’re serious about scaling up or streamlining your apple-related product line, investing in this equipment is a smart move.