If there’s one thing that unites people across cultures, ages, and time zones, it’s this: the irresistible crunch of a potato chip. Whether you’re munching during a movie marathon or sneaking a handful between meetings, chips are the world’s favorite guilty pleasure.

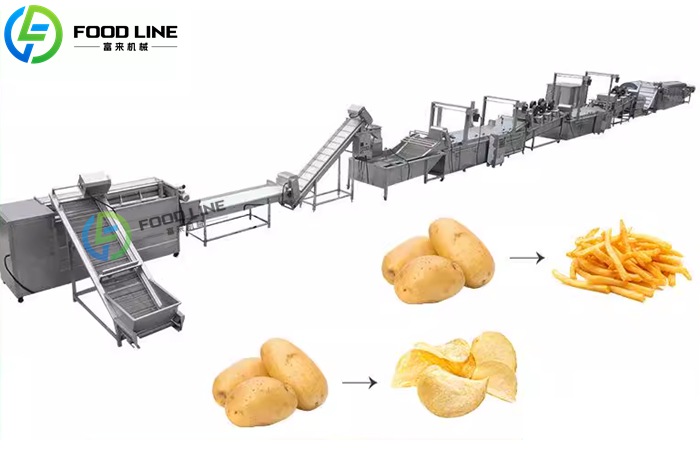

But have you ever wondered what it takes to create that perfect, golden crisp? Spoiler alert: it’s not just slicing and frying. Behind every bag is an intricate dance of machines, technology, and timing. If you’re looking to dip your toes—or rather, your potatoes—into the world of manufacturing, the FoodLine potato chips production line for sale might just be your golden ticket.

What Are the Main Steps in the Potato Chips Production Process?

| Step | Process | Description |

| 1 | Washing & Peeling | Potatoes are thoroughly cleaned and peeled with minimal waste. Think spa day—but for spuds. |

| 2 | Slicing | High-speed potato slicer machines cut the potatoes into thin, uniform slices. It’s precision meets speed. |

| 3 | Rinsing & Blanching | Removes excess starch to prevent browning and improve crispiness. |

| 4 | Drying | Air-drying gets rid of excess moisture—because soggy chips are a tragedy. |

| 5 | Frying | The magic moment. Slices are fried at high temperatures until golden. |

| 6 | De-oiling | Excess oil is removed, so you don’t get chips swimming in grease. |

| 7 | Seasoning | Flavor party! Chips are tumbled with seasonings of your choice. |

| 8 | Cooling & Packing | Finally, they’re cooled and sealed in bags to lock in freshness and flavor. |

Can the Production Line Process Other Types of Chips?

Absolutely! While his production line is optimized for potato chips, they aren’t monogamous. Sweet potato? Cassava? Even beetroot? Yep. As long as it slices, fries, and crunches—it qualifies.

Want to explore your options? Check out our product line for inspiration on versatility.

Pro Tip: Adjustments to blade types, frying times, and seasoning stations can help you experiment with different chip varieties without reinventing the wheel (or buying a whole new line).

What About Food Safety and Hygiene?

I’m glad you asked, because this is where things get serious.

Modern lines like the FoodLine potato chips production line are designed with hygiene in mind. Stainless steel structures, automatic cleaning systems, and minimal human contact ensure that what goes in your mouth is clean, safe, and FDA-compliant.

Our systems also include:

- Closed-loop oil filtration (keeps oil cleaner, longer)

- HEPA filters and sealed conveyors

- HACCP-compliant layouts for inspection readiness

And yes, if you’re scaling up, you’ll sleep better knowing your facility won’t be a nightmare for food inspectors.

How Much Labor is Required?

Here’s the beautiful part—not much.

Thanks to automation, the heavy lifting is done by the machines. In a mid-scale setup, you might need:

- 1 Operator to supervise the line

- 1 Technician to handle maintenance

- 1-2 Packers depending on packaging automation

Compare that to traditional methods where a small army is peeling, slicing, and frying by hand, and the ROI becomes deliciously clear.

Why the FoodLine Potato Chips Production Line?

I’ve seen a lot of machines (seriously, way too many), but the FoodLine line hits that sweet spot of affordability, automation, and quality. Whether you’re a startup snack brand or scaling your snack factory, it brings:

- Consistent output

- Low operating costs

- Modular design (grow as you go!)

- 24/7 support from FoodLine’s team

Plus, they look sleek. I mean, if you’re going to run a factory, might as well have one that’s Instagram-worthy, right?

Wrapping It Up: Your Crunchy Business Awaits

So here we are. You started this post maybe thinking, “Chips are simple,” and now you know they’re not just delicious—they’re a surprisingly sophisticated product backed by smart machines and even smarter decisions.

If you’re seriously thinking about launching a chip brand or expanding production, the FoodLine potato chips production line for sale is a stellar place to start. It’s efficient, hygienic, scalable, and dare I say, kind of sexy (as far as machines go).

👉 Ready to make your business as crispy as your chips? Explore more at FoodLine and start cooking up your legacy.