Poultry is one of the most consumed sources of protein worldwide, and the demand for chicken, turkey, and duck meat continues to rise. If you’re planning to invest in a poultry processing plant or looking to scale up production, take a look at this automatic poultry slaughtering machine.

300-800BPH Automatic Chicken Processing Line

| Type of birds | Chicken |

| Capacity | Speed adjustable 300-1000BPH |

| Finished products | Whole chicken |

| Stunning | Included |

| Killing | manual |

| Bleeding time | 4 minutes |

| Scalding time | 90 seconds |

| Heat supply | Electric heating |

| Scalding temperature | 52-61℃, depending on the chicken data |

| Evisceration | Manual on line |

Automatic chicken poultry killing equipment for sale

The poultry slaughtering machine is specialized equipment that automates the killing, scalding, defeathering, eviscerating, and chilling of poultry. These machines are designed to reduce human labor, improve sanitary standards, and increase overall productivity.

Overhead Conveying Line

The overhead conveyor ensures that each bird moves smoothly from one stage to the next—stunning, bleeding, scalding, defeathering, evisceration, and chilling—without unnecessary handling.

Live Bird Reception & Hanging

- Birds are transported from the farm to the slaughterhouse.

- Workers carefully transfer live birds from crates onto the overhead conveyor line using shackles or hooks.

- This system ensures safe, humane, and efficient handling.

Chicken stunning machine

- Birds are transported from the farm to the slaughterhouse.

- Workers carefully transfer live birds from crates onto the overhead conveyor line using shackles or hooks.

- This system ensures safe, humane, and efficient handling.

Killing & Bleeding

- After stunning, birds are automatically directed to the killing station.

- Mechanical or manual slaughter knives are used depending on the plant setup.

- Birds are then placed in bleeding tunnels or cones for clean blood drainage (2–3 minutes).

Chicken Scalding

- Birds move through a scalding tank filled with hot water (50–65°C).

- Purpose: Loosen feathers for easier plucking.

- Modern scalders come with temperature control, water circulation, and energy-saving features.

Chicken Defeathering /Plucking

- Birds pass through a poultry feather plucking machine.

- Rubber fingers rotate at high speed to remove feathers quickly and efficiently.

- Suitable for chickens, ducks, and turkeys with adjustable settings.

Head & Feet Removal

- Automated units cut off heads and feet cleanly.

- These by-products can be collected separately for further processing or disposal.

Evisceration (Internal Cleaning)

- The abdominal cavity is opened, and internal organs are removed.

- Automatic evisceration machines minimize contamination risk.

- Separate and process edible organs (like liver, heart, gizzard) for sale.

Chilling (Air or Water)

- Birds are transferred to air chilling tunnels or water immersion chillers.

- Temperature is reduced to below 4°C to preserve freshness and prevent bacterial growth.

- Air chilling produces a drier surface, while water chilling increases yield.

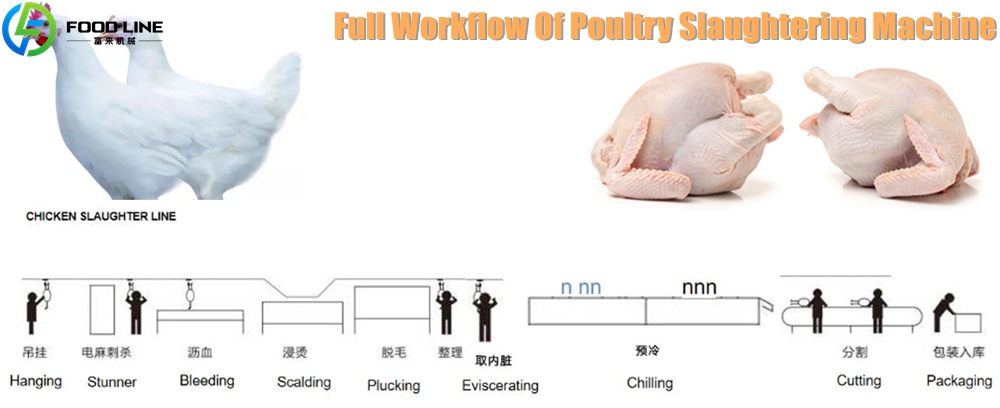

How Does a Poultry Slaughtering Machine Work?

The process is designed for hygiene, efficiency, and animal welfare.

- Stunning & Slaughtering – Birds are stunned (electrically or via controlled atmosphere) for humane slaughter.

- Bleeding – Placed in cones or automated systems for controlled blood drainage.

- Scalding – Birds enter a hot-water tank (50–65°C) to loosen feathers.

- Defeathering – Feather removal using plucker machines with rotating rubber fingers.

- Evisceration – Internal organs removed with minimal contamination risk.

- Washing & Chilling – Processed poultry cooled in water or air chillers to preserve freshness.

Full Workflow Diagram

- Hanging → 2. Stunning → 3. Killing & Bleeding → 4. Scalding → 5. Defeathering → 6. Head & Feet Removal → 7. Evisceration → 8. Washing → 9. Chilling → 10. Packing

Benefits of an Overhead Poultry Conveyor

- Continuous Processing – Keeps production flowing without interruptions.

- Hygiene & Safety – Reduces manual contact, lowering contamination risks.

- Labor Savings – Eliminates the need for workers to carry or manually transfer birds.

- Flexibility – We can customize it in length, height, and speed to match different plant layouts.

- Durability – Built from stainless steel or food-grade materials for long-lasting use.

Invest the poultry slaughtering equipment

Upgrade your poultry business today! Contact us now to get the latest poultry slaughtering machines at competitive factory prices.