Commercial freeze drying equipment, also known as industrial lyophilizers, is used to remove moisture from products by freezing them and then reducing surrounding pressure to allow the frozen water to sublimate directly into vapor. This process retains the product’s shape, nutrients, flavor, and chemical composition.

Choose the model of Vacuum Freeze Drying Machine for Fruits & Vegetables

| Model | FLFD-NDO.2 | FLFD-ND1 | FLFD-NH5 | FLFD-NH10 | FLFD-NH20Z | FLFD-NH30Z |

| Drying Area(㎡) | 0.18 | 10 | 25 | 50 | 100 | 125 |

| Standard warehousing capacity(kg/container) | 0.6~1.5 | 8~10 | 50~80 | 90~120 | 150~200 | 300~800 |

| Number of Tray(pcs) | 2 | 4 | 12 | 20 | 56 | 68 |

| Size of Tray(mm) | 310*290*30 | 533*513*30 | 710*63*35 | 790*630*30 | 690*570*30 | 710*630*35 |

| Size of total machines(m) | 1630*850*1900 | 2000*1300*2000 | 5300*2300*2900 | 6300*2300*2900 | 8000*2700*3500 | 8500*3100*3500 |

| Electric heating Power(kw) | 3.7 | 12 | 55.1 | 93.6 | 145 | 121 |

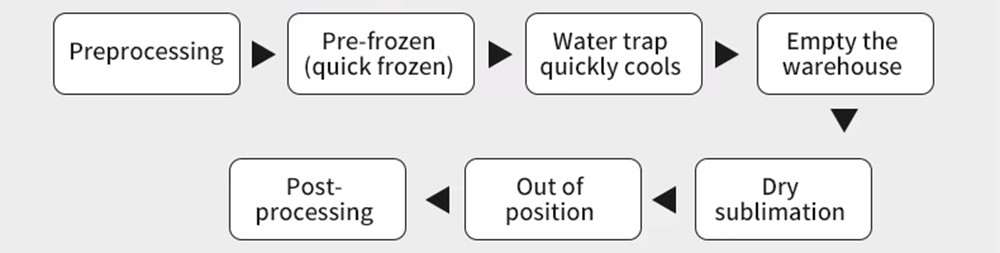

How Does Commercial Freeze Drying Work?

Here’s a simplified breakdown:

- Freezing Phase: The product is frozen, typically below -40°C.

- Primary Drying (Sublimation): Vacuum pressure is applied, and heat gently encourages ice to sublimate (solid to vapor).

- Secondary Drying (Desorption): Residual moisture is removed to achieve <1–5% moisture content.

The result? A lightweight, shelf-stable product with near-perfect retention of structure and nutrients.

Features of Commercial Freeze Drying Equipment

- Batch Capacity: From 10 kg to over 1000 kg per cycle

- Chamber Construction: Prefer stainless steel for hygiene and durability

- Vacuum Pumps: Oil-sealed or dry scroll for efficiency

- Shelf Uniformity: Even heat distribution means consistent product quality

- Automation: PLC controls, touchscreen HMI, remote access

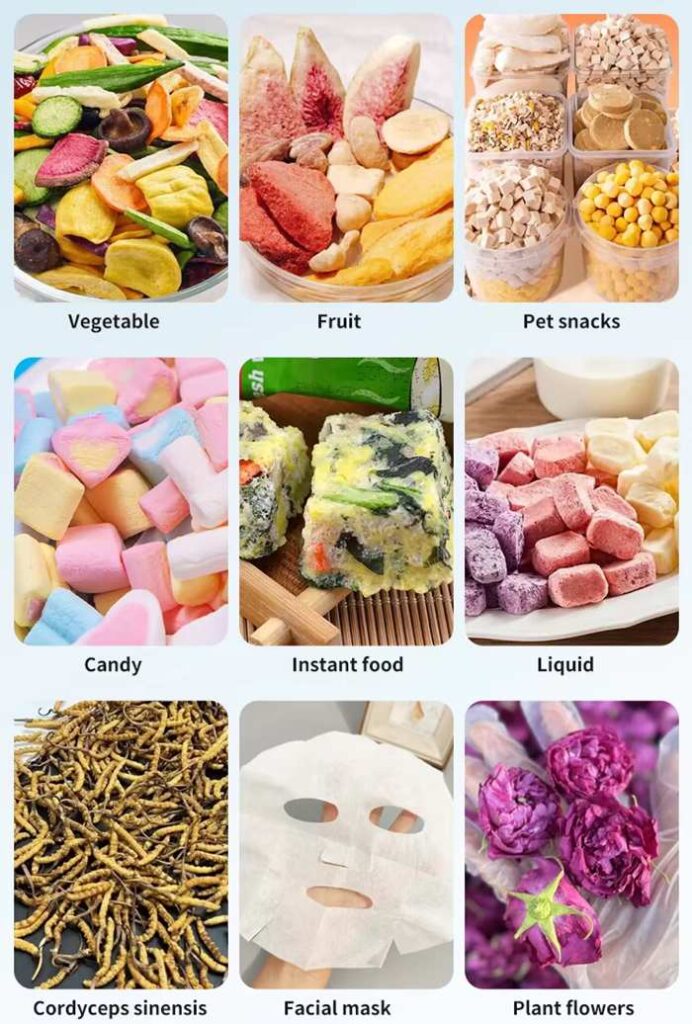

Industries Using Commercial Freeze Dryers

This industrial freeze dryer is used across a wide range of industries where moisture-sensitive products require preservation without compromising quality.

- Food & Beverage: Fruits, vegetables, meats, herbs, dairy, coffee

- Pharmaceuticals: Vaccines, proteins, injectables, antibiotics

- Biotechnology: Cell cultures, enzymes, diagnostic kits

- Pet Food: Freeze-dried raw food, snacks

- Cosmetics & Wellness: Botanical extracts, face masks, vitamins

Frequently Asked Questions (FAQs)

Q1: What is the difference between vacuum drying and freeze drying?

Vacuum drying uses heat under vacuum; freeze drying uses sublimation at low temperatures, preserving structure and bioactivity.

Q2: How long does a freeze drying cycle take?

Typically 12–36 hours, depending on product thickness, moisture, and system design.

Q3: Can I freeze dry liquids?

Yes—liquids like soups or extracts can be pre-frozen in trays or vials for batch drying.

Q4: Is freeze drying better than air drying?

Absolutely—for sensitive materials like food, enzymes, or pharmaceuticals, freeze drying maintains superior quality.

Q5: How much space does a commercial freeze dryer need?

Depends on size. Small home freeze dryer may need 2–5 m², while large industrial systems may require over 20 m².