Cookies are the most common snack for us—universally loved, endlessly customizable, and always satisfying. From a quick coffee companion to a lunchbox essential, cookies have secured their place in snack culture around the globe. Whether you prefer them soft and gooey, crisp and buttery, or filled with cream, there’s a type of cookie for every craving—and a machine that makes it possible.

So today, we will talk about the cookies production.

Types of Cookies & Biscuits—and What Machines You’ll Need

Each type of biscuit has unique dough characteristics, baking requirements, and forming techniques. Here’s a closer look:

1. Wire-Cut Cookies (Soft & Chunky Types)

Examples: Chocolate chip cookies, oatmeal raisin, butter cookies

Texture: Soft or chewy

Dough Type: Sticky and soft dough, often containing inclusions (chips, nuts, etc.)

✅ Machines Needed:

- Dough Mixer: For uniform mixing of soft dough.

- Wire-Cut Cookie Machine: Cuts and drops dough through a wire, forming even-sized pieces.

- Tunnel Oven: Continuous baking with controlled temperature zones.

- Cooling Conveyor: Prevents warping and ensures proper cooling.

- Packaging Machine: For flow wrapping or tray packing.

🔧 Pro Tip: Look for a cookie depositor with adjustable nozzles for different shapes and sizes.

2. Rotary Moulded Cookies (Crunchy Butter Biscuits)

Examples: Digestive biscuits, shortbread, Marie biscuits

Texture: Crisp and dry

Dough Type: Hard, non-sticky dough

✅ Machines Needed:

- Horizontal Dough Mixer or Planetary Mixer: For stiff, low-moisture dough.

- Rotary Moulding Machine: Presses dough into engraved molds for shape and texture.

- Biscuit Baking Oven: Gas or electric tunnel oven with adjustable heat zones.

- Oil Sprayer (optional): Adds a glossy finish post-baking.

- Stacking & Packaging Line: For neat stacking and fast wrapping.

🛠 Did You Know? Rotary moulders can create ornate surface patterns on biscuits—perfect for branding!

3. Sandwich Biscuits (Cream-Filled)

Examples: Oreo-style cookies, custard creams, lemon-filled biscuits

Texture: Crunchy shells with creamy filling

Dough Type: Similar to rotary biscuits, but combined post-baking

✅ Machines Needed:

- Cookie Forming Line (Rotary Moulder or Wire Cut): For producing top and bottom shells.

- Cream Spreader/Sandwiching Machine: Automatically injects cream and aligns the biscuits.

- Cooling Tunnel: Stabilizes the cream before packing.

- Flow Wrap Packaging Machine: Maintains hygiene and extends shelf life.

🎯 Bonus: Add chocolate enrobers or drizzle lines to create deluxe sandwich cookies.

4. Deposited Cookies (Fancy Shapes or Swirls)

Examples: Piped butter cookies, Linzer cookies, almond swirl

Texture: Light and buttery

Dough Type: Soft and pipeable

✅ Machines Needed:

- Dough Depositor Machine: Deposits soft dough directly onto trays in customizable shapes.

- Rotary Rack Oven or Tunnel Oven: Depending on your production scale.

- Tray Cooling System: Trays pass through cooling conveyors or spiral coolers.

- Decorating Machine (Optional): For chocolate drizzle, nuts, or sugar sprinkles.

🌈 Creative Edge: Some depositors come with dual hoppers—perfect for two-tone cookies!

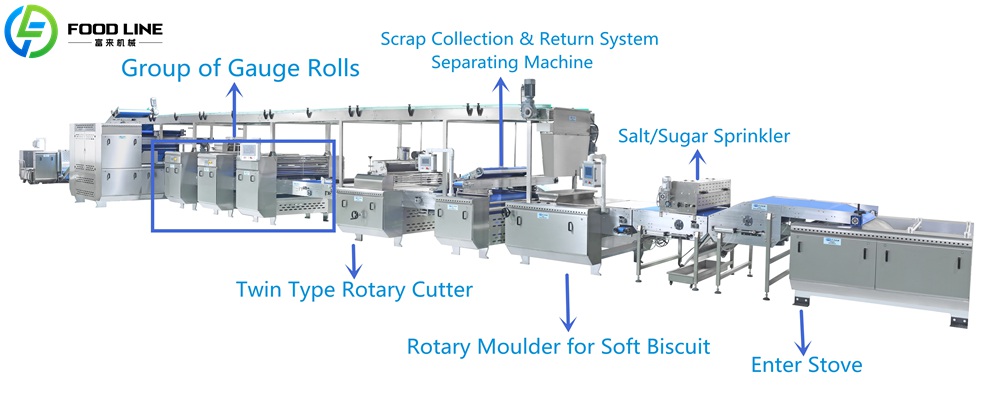

5. Sheeted & Laminated Biscuits (Crackers or Flaky Biscuits)

Examples: Cream crackers, soda biscuits, puff-style snacks

Texture: Light, crispy, multi-layered

Dough Type: Laminated dough with resting time

✅ Machines Needed:

- Laminator & Sheeter: Rolls and folds dough into thin layers.

- Cutting & Docking Machine: Cuts shapes and docks holes to prevent puffing.

- Salt/Sugar Sprinkler (Optional): Adds flavor before baking.

- Tunnel Oven: For consistent, fast baking at scale.

- Cooling & Packing Line: Automated stacking and wrapping.

⚙️ Industrial Level: These lines are often used in large-scale cracker manufacturing.

Overview Table: Biscuit Types & Machines Needed

| Biscuit Type | Dough Type | Key Machines |

|---|---|---|

| Wire-Cut | Soft, sticky | Dough Mixer, Wire-Cut Machine, Oven, Cooling, Packaging |

| Rotary Moulded | Firm, dry | Mixer, Rotary Moulder, Oven, Stacker, Packaging |

| Sandwich Biscuits | Firm, dry | Forming Line, Cream Filler, Cooling Tunnel, Packaging |

| Deposited Cookies | Soft, pipeable | Dough Depositor, Oven, Cooler, Optional Decorating Machine |

| Sheeted Crackers | Laminated | Sheeter, Laminator, Cutter, Oven, Cooling Line, Packaging |

Scaling Production: Complete Cookies Production Line

If you’re producing multiple types of cookies, investing in a modular cookies production line is a game-changer. These systems can:

- Handle multiple dough types

- Switch between wire-cut and deposited modes

- Automate baking, cooling, and packing

- Ensure consistent quality at high output

Common Customizations Include:

- Touchscreen controls for recipe management

- Quick-change molds and nozzles

- Servo motors for high-speed precision

- Integration with quality control systems

Why Invest in Automated Cookie Machines?

Here’s what automation brings to the (cookie) table:

- ✅ Higher Efficiency: Save time and reduce manual labor

- ✅ Consistent Quality: Every batch, every biscuit—uniform and professional

- ✅ Cost Savings: Less waste, optimized ingredients, fewer returns

- ✅ Scalability: Easily increase output as demand grows

Final Thoughts: Choose the Right Biscuit Machinery

Whether you’re crafting buttery shortbread, cream-filled chocolate sandwiches, or artisanal swirled cookies, your production success starts with the right machines. Choose a reliable manufacturer that offers tailored solutions, after-sales service, and the ability to scale with your business.

🛒 Looking for top-quality cookie machines? Contact FoodLine today for customized solutions and turnkey biscuit production lines.

🔍 FAQs About Cookies Production Lines

1. What is the most versatile cookie machine?

A multifunctional cookie depositor can handle various dough types and shapes, making it ideal for diversified production.

2. Can one machine produce both soft and hard cookies?

Some high-end machines offer adjustable settings for dough texture and baking profiles, allowing for multiple biscuit types.

3. How much does a cookie production line cost?

Prices range from $10,000 for a small depositor setup to over $100,000 for a fully automated, multi-functional line.

4. Can these machines handle gluten-free or vegan dough?

Yes, with the right settings and materials, most cookie machines can process alternative doughs like gluten-free, vegan, or keto-friendly options.

![Read more about the article Best Food Trailer for Sale on Amazon [2025 Ultimate Guide]](https://www.foodlinemachinery.com/wp-content/uploads/2025/12/custom-food-truck-300x143.jpg)